联系我们

18560023440

王经理:18560023440

地址:山东省德州市齐河县经济开发区齐众大道7号-2车间

业内资讯

业内资讯

雕刻机断刀的原因及解决方法

来源:http://www.jmycnc.com 时间:2022-04-12

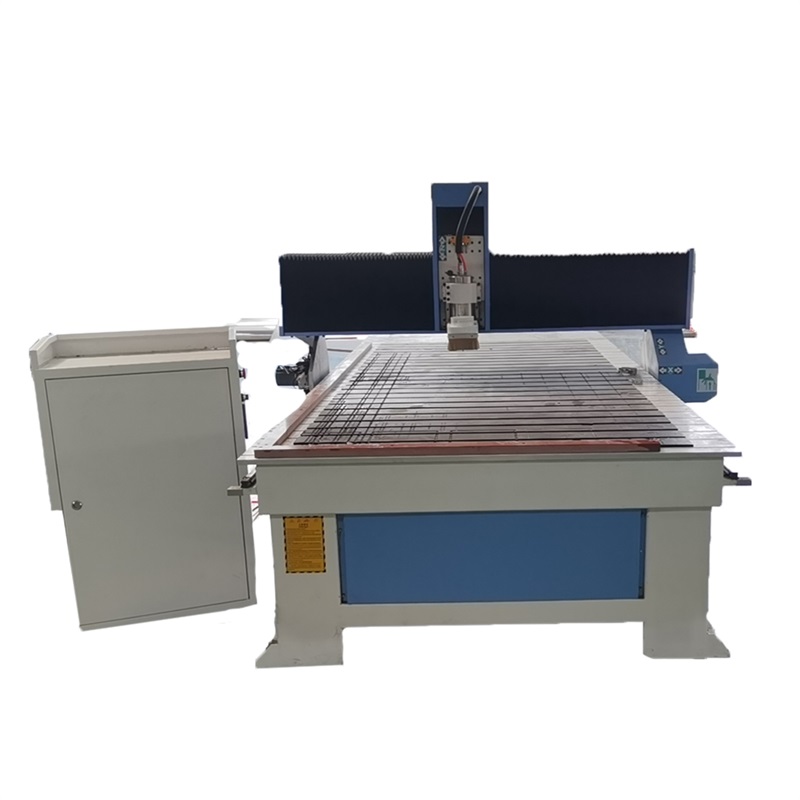

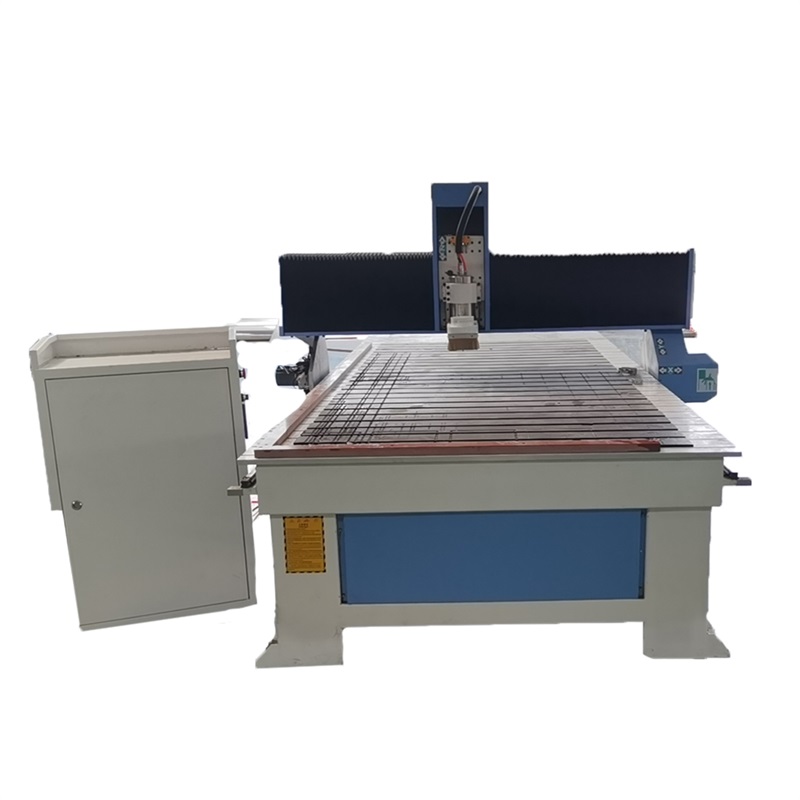

雕刻机在使用过程中,难免出现断刀的现象,主要是因为雕刻刀具不足以承受当前的切削力。也有可能是因为操作人员操作不当导致。下面总结一下导致雕刻机断刀的各种原因,希望对各位雕刻机用户有帮助。

In the process of using the engraving machine, it is inevitable to break the tool, mainly because the engraving tool is not enough to bear the current cutting force. It may also be caused by improper operation of operators. The following is a summary of the various reasons for the cutter breakage of the engraving machine, hoping to be helpful to all engraving machine users.

1、是雕刻加工的材料问题,如果被加工的材料本身硬度不均匀、杂质较多等都会引起断刀。

1. It is the material problem of engraving processing. If the hardness of the processed material itself is uneven and there are many impurities, it will cause knife breakage.

2、是雕刻机所连接的电压问题,如果电源电压不稳定,也会引起刀具的断损。

2. It is the voltage problem connected to the engraving machine. If the power supply voltage is unstable, it will also cause the cutting tool to break.

3、所选用刀具的硬度、强度、锋利程度以及刀杆的长度有关,要根据所加工材料的不同选用合适的刀具。

3. The hardness, strength and sharpness of the selected cutting tools are related to the length of the tool bar. Appropriate cutting tools should be selected according to the different processing materials.

4、雕刻材料固定不好、刀具装夹不牢固、刀杆和主轴不同心的情况下会因为主轴高速旋转刀具晃动,引起断刀。

4. When the engraving material is not fixed well, the tool clamping is not firm, and the tool rod and the spindle are not concentric, the tool will be broken due to the high-speed rotation of the spindle and the shaking of the tool.

5、雕刻机雕刻是对雕刻指令的执行,包括位置指令和速度指令,加工程序的正确与否也会对刀具有影响。

5. Engraving machine engraving is the execution of engraving instructions, including position instructions and speed instructions. Whether the processing program is correct or not will also have an impact on the knife.

6、雕刻机床的启动速度不要设置过高,启动速度也高越容易引起机床震动,也容易导致断刀。

6. The starting speed of the engraving machine tool should not be set too high. The higher the starting speed is, the more likely it is to cause vibration of the machine tool and tool breakage.

7、雕刻机主轴的转速高低影响,雕刻同样的产品,主轴转速过低的情况下,刀具切削力变大,而主轴扭力不变就会引起断刀,所以使用的主轴转速还是要偏高一些。

7. The rotation speed of the main shaft of the engraving machine affects the engraving of the same product. When the rotation speed of the main shaft is too low, the cutting force of the tool becomes larger, and the constant torsion of the main shaft will cause tool breakage. Therefore, the rotation speed of the main shaft used is still higher.

8、单次下刀的程度设定,吃刀量过小,加工时间变长;吃刀量过大,刀具承受不了也会断刀。

8. The degree of single cutting is set, the cutting amount is too small, and the processing time becomes longer; If you eat too much, the knife will break if it can't bear it.

9、机床的加工范围和使用刀具是否符合所加工材料?雕刻机床与地面是否平稳也可能引起断刀。

9. Is the machining range and tool of the machine tool consistent with the processed materials? Whether the engraving machine tool is stable with the ground may also cause knife breakage.

10、在雕刻硬质材料例如大理石、花岗岩、玻璃以及金属材料的时候,是否有使用专用润滑剂润滑。

10. Whether special lubricants are used when carving hard materials such as marble, granite, glass and metal materials.

11、雕刻软性金属材料例如铜铝或者其他熔点较低的材料例如塑料材质的时候刀具排屑不畅也是引起断刀的原因之一。

11. When carving soft metal materials such as copper and aluminum or other materials with low melting point such as plastic, poor chip removal of the tool is also one of the reasons for tool breakage.

以上原因大体涵盖了雕刻机断刀的原因,如果排除了以上情况,仍然出现断刀现象,建议联系雕刻机生产厂家或者经销商实地排查。

The above reasons generally cover the reasons for the knife breaking of the engraving machine. If the above conditions are excluded and the knife breaking still occurs, it is recommended to contact the manufacturer or dealer of the engraving machine for on-site investigation.

以上就是为大家介绍的有关玉石雕刻机的详细介绍,希望对您有所帮助.如果您有什么疑问的话,欢迎联系我们.我们将以的态度,为您提供服务http://www.jmycnc.com/

The above is the detailed introduction of jade carving machine. I hope it will help you If you have any questions, please contact us We will provide you with professional service http://www.jmycnc.com/

- 上一篇:石材雕刻机在使用过程为什么要加水?

- 下一篇:泡沫雕刻机日常井盖如何进行维修保养?