联系我们

18560023440

王经理:18560023440

地址:山东省德州市齐河县经济开发区齐众大道7号-2车间

新闻资讯

新闻资讯

泡沫雕刻机怎样直上直下进行打孔?

来源:http://www.jmycnc.com 时间:2021-09-17

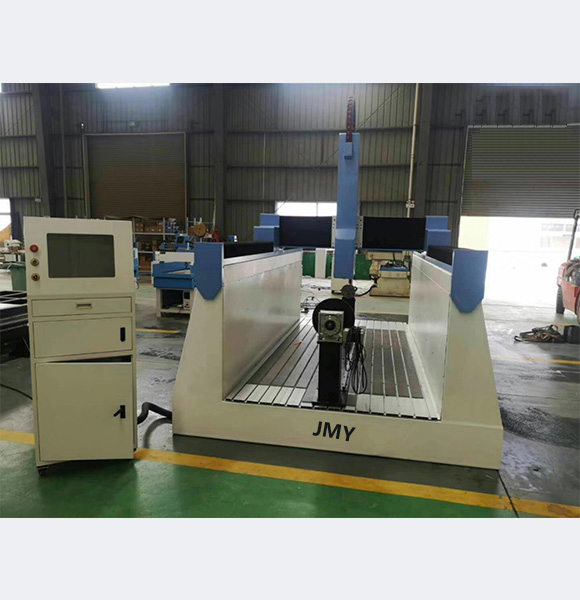

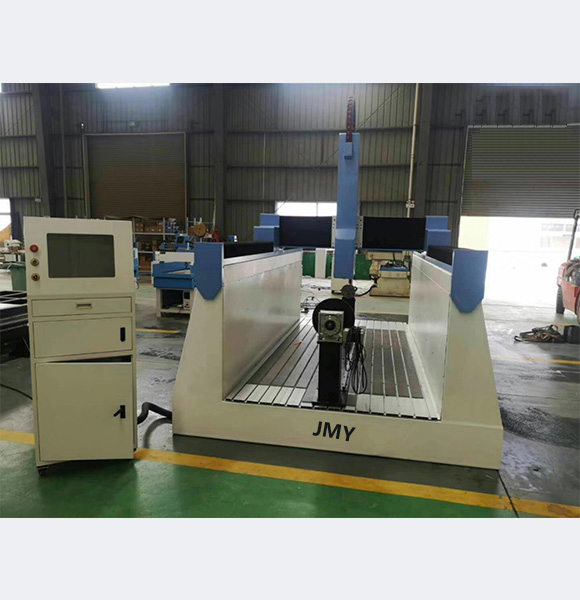

泡沫雕刻机在雕刻加工领域可算是一位“全能型选手”,无论是精美的雕刻工艺,还是批量的雕刻切割都“不在话下”,其中可以进行打孔的这个功能自然不可忽视。

Foam carving machine can be considered as an all-around player in the field of carving, and it be nothing difficult to do, whether it is exquisite carving or batch carving.

由于泡沫雕刻机并不是专门用于进行打孔的,所以在打孔深度、打孔效率等方面相比于专门的打孔机较为逊色,但是使用泡沫雕刻机进行打孔何尝不是有着自己特殊的优势和特点,例如泡沫雕刻机的钻头更容易人们操作控制,便于进行直上直下的垂直孔的加工。

Because the foam engraving machine is not specially used for drilling, it is inferior to the special punching machine in the aspects of punching depth and drilling efficiency. However, the use of foam engraving machine does not have its own special advantages and characteristics, for example, the bit of the foam carving machine is easier for people to operate and control, so as to facilitate the processing of vertical holes directly up and down.

在通过泡沫雕刻机进行打孔的过程中,要对雕刻路径的绘制格外注意,各项尺寸都要多加确认。在参数调节的过程中与产品直接进行尺寸以及位置的确定,这样才能大程度上保证打出的孔洞符合要求。同时,还需要特别注意的是绘制的孔洞路径与泡沫雕刻机软件版面的关系。

In the process of punching through the foam engraving machine, we should pay special attention to the drawing of the carving path, and all dimensions should be confirmed. In the process of parameter adjustment, determine the size and position directly with the product, so as to ensure that the drilled holes meet the requirements to a great extent. At the same time, special attention should be paid to the relationship between the hole path and the software layout of the foam carving machine.

打孔路径的设计绘制是使用泡沫雕刻机进行绘制的关键步骤,除此之外便是泡沫雕刻机所使用的钻头了,其所能达到的大的转速等工作性能都直接影响着泡沫雕刻机进行直上直下的打孔工作。另外,待加工材料的硬度也会对泡沫雕刻机的打孔工作产生一定的影响,所以在实际进行操作以前,需要提前对泡沫雕刻机的加工硬度和材料进行比较分析。

The design and drawing of the perforating path is the key step of using the foam engraving machine to draw. Besides this is the bit used by the foam carving machine. The working speed of the foam carving machine directly affects the direct drilling work of the foam engraving machine. In addition, the hardness of the material to be processed will have a certain effect on the punching work of the foam engraving machine, so before the actual operation, the hardness and material of the foam engraving machine need to be compared in advance.